Jointer vs Planer – Which is Best for Your Needs?

-

- Last updated:

If you’re a serious woodworker, you’ve probably figured out one key fact about your supplies. Rarely, unless you’re paying a premium for it, you’re likely to end up with less-than-perfect wood to start your project. That’s a problem because it’s going to affect your work and the final product. It’s so much easier to begin with lumber that is a uniform shape and thickness. Otherwise, you’ll fight it all along the way.

You also have to consider the final product.

Lumber that you’ve perfected with a jointer and planer makes your job easier. It also produces a quality product that has a professional look to it. These tools perform similar but different tasks that contribute to the final result. If you’re wondering if you need both, our guide will give you the info you need to make an informed choice based on your lineup of projects.

Overview of the Jointer

Both a jointer and planer are tools you’ll use to prepare your lumber for your project. They aren’t things you’ll reach for to finish something. Their purpose is to make your job easier by removing the imperfections that you’ll undoubtedly find. Both are also worth the investment if just for the time you’ll save. A jointer makes working with imperfect wood easier. It can also save you some money in the long run.

Its task is to get rid of the bumps and bows that you’ll inevitably find with lumber. The result is even working surfaces and edges. Let’s face it. The wood you’ll get no matter what the source likely has a few blemishes. Knots may affect its appearance and, in turn, the workability of the lumber. The result is an even surface that will mesh better with other boards and give your project a professional look.

- See Also: 6 Best Jointer Planer Combos

How It Works

A jointer is the more complicated of the two tools, given its purpose. Its job is to give you a flat surface on each piece of lumber. Its function is similar to a hand plane in that regard. The wood you buy often comes from different sources. That usually translates into varying qualities. A jointer neutralizes these effects and gives you an even playing field, which is the best place to start any project.

A cutter head lies between two planes. Guides on the sides ensure that you get even cuts across the surface of each piece. That action gets rid of the bumps that add unwelcome variation to them, caused by twists and bends in the lumber. Remember that the wood is relatively wet when it’s first milled. It may start to dry unevenly, which, in turn, twists each piece.

When to Choose a Jointer

You should use a jointer when you’re dealing with raw lumber of varying quality. It evens the playing field to make your job easier. You don’t have to inspect each piece to see if it’ll work. They are all the same! It’s a part of the preliminary work you’ll do on a project. One of the biggest advantages of using a jointer is that you can work with sub-par lumber and still make it work for your job.

Yes, it will generate waste, but that factor is in proportion to the quality of wood from which you start. A jointer cuts the pieces from below to smooth out the surface. However, you must balance it with the result. It also squares the edges for you, which can save you time and produce better results. It’s essential to inspect the supply before you buy to reduce the waste with rough pieces.

Quality Considerations

As you may surmise, it’s worth investing in a quality product to realize the benefits of using this tool. Otherwise, you’ll end up with a tool that requires more maintenance. Size is an issue if you are a serious DIYer taking on more extensive projects. That also means you’ll pay more for this device. It’s one of those products that costs a lot but is worth it if you use it a lot.

- Flat surfaces and squared edges produced

- Cost savings using otherwise imperfect lumber

- Adjustable

- Waste generation

- Large footprint

- Considerable investment for larger projects

Overview of the Planer

The primary function of a planer is the uniform thickness of the boards. It takes the functionality of a jointer to the next level for professional results. Remember that a jointer produces uniform lumber. The planer ensures that it is of the correct thickness for the project so that it is flush where needed. It is by far the older of the two tools, with a history stretching back centuries.

How It Works

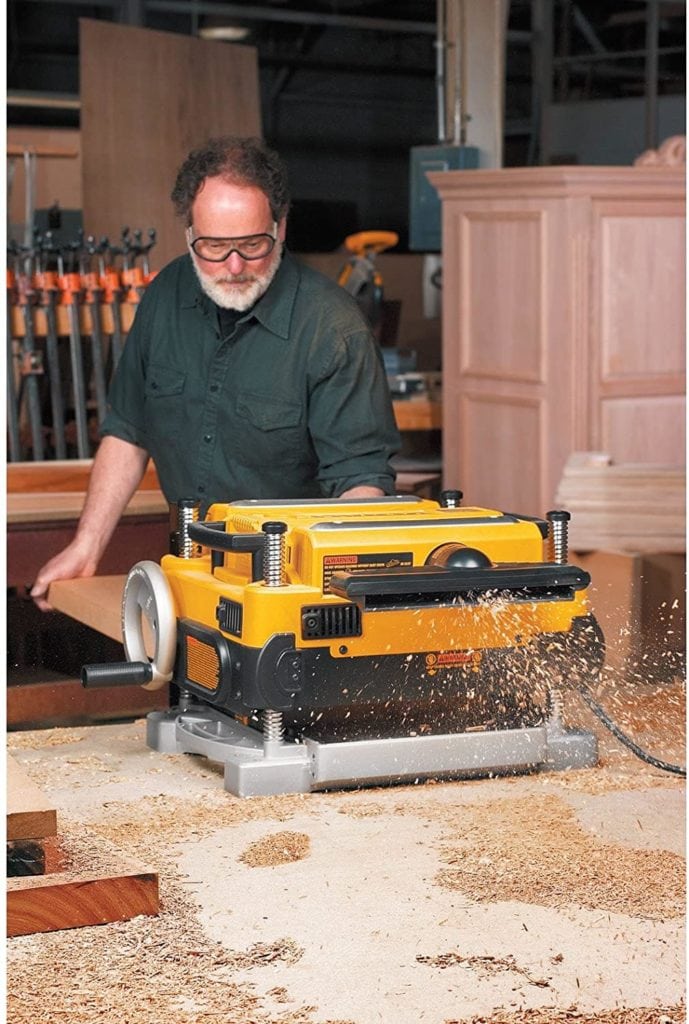

Unlike the jointer, a planer cuts from above to give you the correct thickness of each board. The recommended method is to begin with a board that you’ve smoothed with a jointer. Flip it so that the smooth surface is down. Then, use the planer to replicate the process on the rough side. Cutting with the grain will produce a smooth finish without splintering. The results are worth the effort.

When to Choose a Planer

Technically, you could use a planer to smooth both sides of the boards. However, it is an acquired skill that takes some practice. A planer is an essential tool if you are working with unfinished wood. Its best use is as a follow-up to the perfecting that the jointer does. That will make woodworking far less time-consuming by using it as the final step toward beginning your project than using it on rough lumber.

- Professional results

- Specialty tools for different projects and wood pieces

- Easy to use

- Uniform thickness and parallel surfaces

- More expensive than a jointer

- Less efficient with rough lumber

Buyer’s Guide

If you’re serious about honing your woodworking skills, a jointer and planer are essential tools to handle the routine starts of most projects. While they may sound similar, each one does a specific job that together can save you time and money in your workshop. What the jointer excels at doing, the planer falls short and vice versa. On the downside, both are often expensive, depending on the type and size you get.

Type

Both tools include a variety of subtypes that influence both the cost and the usage of the device. Understanding the pros and cons of each one can help you make an informed choice. Bear in mind that there are combo products on the market if you have limited space.

Jointer

You’ll have your pick of four kinds of jointers based on their size and design. They include:

- Benchtop

- Tabletop

- Open stand

- Closed stand

The benchtop is the smallest and lightest of the bunch. They include the basic features of guides and fences to keep the board straight as you feed them into the machine. A metal or cast-iron body is the best choice for durability.

The tabletop is suitable for projects that involve wider and thicker lumber because of its larger surface. However, that also means that you’re not going to move this one around once you assemble it, although it brings more power to the forefront.

Open-stand jointers are free-standing tools that offer portability if you need this tool at different job sites. It’s essential to balance their convenience with the disadvantages of the vibrations and noise they produce. A closed-stand jointer doesn’t have these cons because of its design. On the downside, they are bulky and not portable.

Planer

You’ll see all-purpose hand planers or electrically powered ones for larger jobs. The former has a simple design that is easy to use. You’ll find uniform sizes across the board with different manufacturers to help you select the right one for the job. There are also specialty tools designed for working on various surfaces. They differ in their smoothing and flattening capabilities based on their length and width.

The different types are appropriate for the particular finishing stage. For example, you might use a scrub planer to rough out a board to start the process. A smoothing planer is the tool of choice to prepare the lumber for the final phases before the work on your project commences. There are also tools for specific jobs, such as working on toys or cutting grooves.

Adding to your choices are manual hand planers and electric handheld ones. The former is labor-intensive to use, but it gives you precise control. The latter is an excellent compromise and ideal for smaller tasks.

Dust Collection

Both tools will generate a lot of waste and dust. We recommend looking for products that can help manage this issue, whether it has a collection bag or an attachment for a shop vac. It will make a healthier work environment and save you time on cleaning.

Price

Entry-level products for either tool will likely run you at least a couple of hundred dollars for a quality model that includes a guarantee and manufacturer warranty. The broader range of boards that either can handle will also drive up the price. Top-end jointers and planers can easily go north of four figures. Therefore, it’s essential to think about the mission-critical features you need in these products.

Consider the type of projects you do and whether portability is a must-have. If space is an issue, measure how much room you can spare, especially if it’s going to take up residence in your shop. All of these factors can affect the price you’ll pay for a jointer and planer—or both!

Tool-Specific Considerations

Durability is a vital factor for either tool. That point rests with the construction and design of the product. Tools made of solid metal are ideal for handling the vibrations and jarring that is par for the course when using either one. The noise level is another essential thing to consider. Most manufacturers will list a decibel spec to help you compare the models. However, there are also some specific features for each tool.

- Board width and thickness

- Angled stops

- Tilt capacity

- Number of irons

- Locking guides or clamps

- Preset thickness sizes

- Cuts per inch

Do You Need Both a Jointer and Planer?

The short answer is yes unless you have the skill and patience to do both tasks with one of them or opt for a combo device. If you must choose one over the other, a planer will cover more bases than a jointer. The fact remains that you can buy finished lumber and negate the need for a jointer. However, you still have to ensure a uniform thickness of the boards regardless of how straight they are.

Conclusion

The different uses of a jointer and planer highlight the specialization of these tools. While a planer can step up to the plate, it means more work and time to prepare your materials. It also requires precision and accuracy that only come from experience. If you do a lot of woodworking, getting both is a wise investment if just for the money you’ll save on lumber.

Related posts:

- Hand Planer vs Bench Planer: Which is Best for Your Needs?

- Drum Sander vs Planer – Which is Best for Your Needs?

- WEN 6550 Thickness Planer Review

Contents