How Does a Circular Saw Work? (with Pictures)

-

- Last updated:

A circular saw is the first tool many carpenters will reach for during a project. It’s useful for making long, straight cuts, and for cutting store-bought lumber into the right shapes and sizes for the job. Sometimes called a “skill saw”, it’s also one of the most intuitive woodworking power tools for beginners – but should still be treated with respect.

Parts of a Circular Saw

Circular saws have roughly five main parts. Let’s take a quick look at what makes a circular saw work:

Motor

The blade of a circular saw is driven by a high-speed motor – typically running between 5,300 and 5,800 revolutions per minute when not actively cutting. Most circular saw motors are electric, either plugging into extension cords or running on rechargeable lithium-ion batteries.

Blade

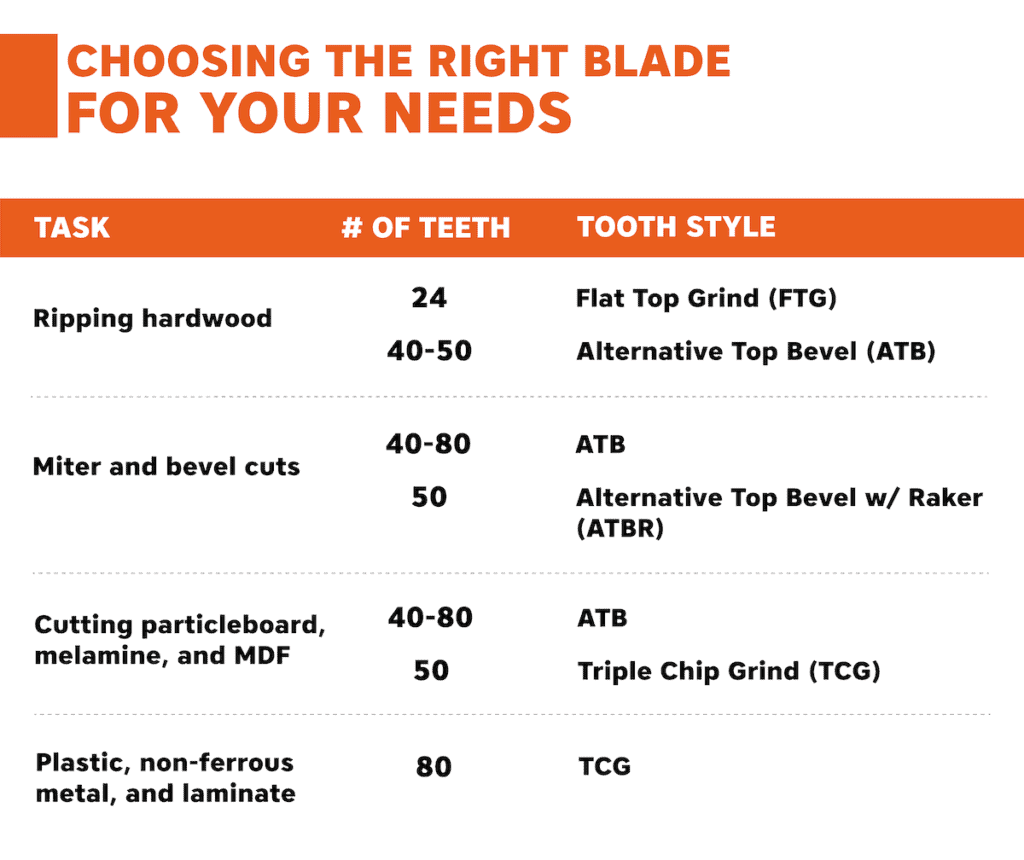

Circular saw blades come with different numbers of teeth, with more teeth generally equaling a more precise cut. Toothier blades are good at cutting across the grain of the wood, while blades with fewer teeth are best for cutting with the grain.

The standard size of a circular saw’s blade is 7¼ inches, though smaller and larger blades exist. The gullets, the spaces between the teeth, are also important, as they clear sawdust and wood chips away while the saw cuts. Larger gullets are better for woods that break down into larger chips.

Blade Guard

The blade guard is the circular saw’s most important safety feature. It’s comprised of an opaque fixed guard, which covers the top half of the blade and never moves, and a transparent floating guard, which covers the bottom half of the blade while the saw is not in use.

For additional safety, some circular saws might have a switch that must be released before the blade can move.

Base Plate

The base plate, also called the shoe, is a piece of metal attached to the leading edge of the saw, opposite the handle and perpendicular to the blade. It rests on whatever you’re cutting and ensures the blade holds to a straight line. Most base plates can be adjusted up and down for different thicknesses of material or tilted up to a 45-degree angle for bevel cuts.

More modern circular saws often have laser guides attached to the base plate. Lasers are another way to make absolutely sure you’re cutting a straight line.

Handles

Finally, circular saws have two handles: one at the back of the blade guard that includes the trigger switch for starting the blade, and one on top of the blade guard that helps you hold the saw steady.

Uses of a Circular Saw

Circular saws can make four kinds of cuts: rip cuts, crosscuts, miter cuts, and bevel cuts.

- Rip cuts are the easiest cuts to make. Cutting along the grain of the wood is like tearing along a perforation — the wood “wants” to be cut this way. Accordingly, your blade doesn’t need to be as precise and can achieve a straight cut with fewer teeth (28 or more).

- Crosscuts cut across the grain of the wood. These cuts are more difficult since the wood will “resist” you. To get the same clean precision on a crosscut that you can on a rip cut, you should use a saw blade with more teeth spaced closer together (40 or more).

- Miter cuts are cuts made at any angle other than 90 degrees. They can be made with or against the grain of the wood.

- Bevel cuts are the most advanced of all cuts. To make a bevel cut, you’ll need a circular saw with an adjustable base plate. The plate always sits against the wood, so when you angle it, the blade will end up sitting at an angle.

How to Use a Circular Saw

Start by placing your wood, plastic, or metal somewhere you can hold it steady while leaving space below it. Most pro- and semi-pro woodworkers will use sawhorses. After clamping the material into place and making sure it’s stable, adjust the depth of your saw blade so it’s slightly more than the thickness of your workpiece, ensuring you make a clean cut all the way through.

Then, double-check for safety. Make sure you’re wearing eye protection – the saw will fling up dust as it cuts. Remove the floating guard and place the base plate against the work surface, with the blade’s leading edge nearly touching the edge of the workpiece. Grip both handles tightly and disengage the circular saw’s safety switch.

Squeeze the trigger to start the blade. This activates the motor, which begins to rotate the blade, almost always with the leading edge cutting upward. Push the saw forward, gently but firmly, until it touches the workpiece, then continue pushing on through until you’ve completed the cut.

After finishing the cut, release the trigger. Do not lift the saw up or remove your hands from the handles until the blade has completely stopped moving. Re-engage the safety before putting your hands anywhere near the blade.

What a Circular Saw Can’t Do

Circular saws are great, but they aren’t capable of cutting anything other than perfectly straight lines. If you need to cut your workpiece on a curve, go with a reciprocating saw instead, like a jigsaw or a band saw. Those saws are cut with translational instead of rotational motion, which allows the shape of the cut to be more flexible.

- Related Read: Table Saw vs Circular Saw: Which One Should You Choose?

Contents